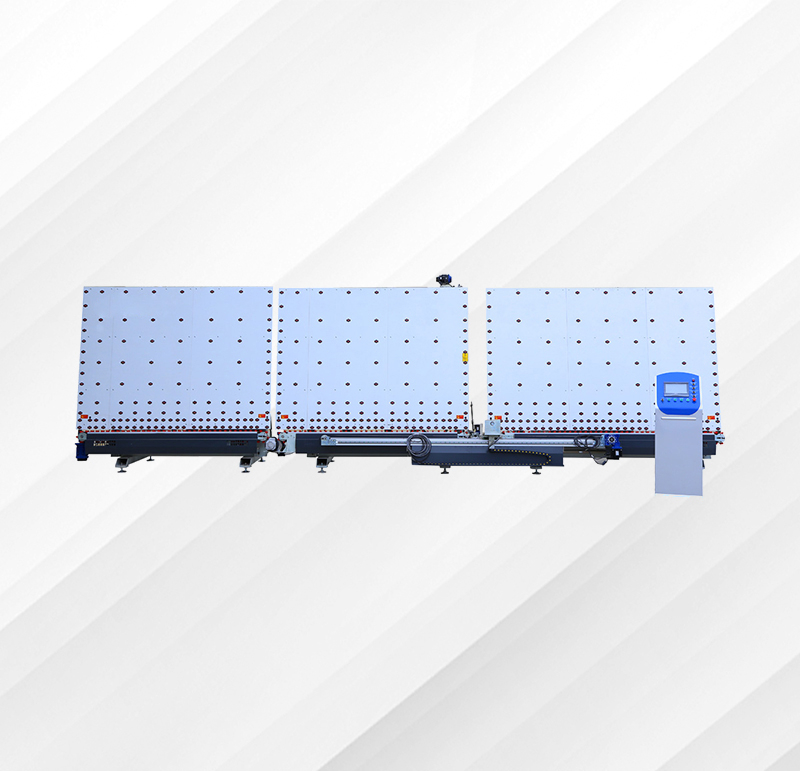

全自動封邊機的溫度的控制與膠線的處理

時間:2023-10-06 來源:http://www.yalais.com/ 發布人:昌盛機械

全自動封邊機封邊時的溫度

The temperature of the fully automatic edge banding machine during edge banding

由于封邊熱熔膠性能受溫度影響,所以在封邊過程中,溫度是非常需要關注的指標。在封邊時的熱熔膠溫度、基材溫度、封邊材料溫度以及工作環境(全自動封邊機所在廠房車間)溫度都是非常重要的封邊參數。在全自動封邊機上由于膠涂在基材上,溫度過低的基材將使熱熔膠提前固化,從而導致膠可以粘在基材上,但卻粘不牢封邊材料,基材的溫度保持在20°C以上。

Due to the influence of temperature on the performance of edge sealing hot melt adhesive, temperature is a very important indicator to pay attention to during the edge sealing process. The temperature of the hot melt adhesive, substrate, edge sealing material, and working environment (workshop where the fully automatic edge sealing machine is located) are all very important edge sealing parameters during edge sealing. On a fully automatic edge banding machine, due to the adhesive being applied to the substrate, a substrate with a low temperature will cause the hot melt adhesive to cure early, resulting in the adhesive being able to adhere to the substrate, but not firmly adhering to the edge banding material. The temperature of the substrate remains above 20 ° C.

全自動封邊機的工作環境溫度會影響到膠的固化速度。工廠往往在溫度低的季節會出現封邊問題,其原因就在于低溫下熱熔膠的固化速度加快,粘接有效時間縮短。如果全自動封邊機的進料速度不能改變(大多數情況下),要保證封邊質量就必須預熱板材和封邊材料。

The working environment temperature of the fully automatic edge banding machine can affect the curing speed of the adhesive. Factories often encounter edge sealing problems during low temperature seasons, due to the accelerated curing speed of hot melt adhesives at low temperatures and the shortened effective bonding time. If the feeding speed of the fully automatic edge banding machine cannot be changed (in most cases), it is necessary to preheat the plates and edge banding materials to ensure edge banding quality.

全自動封邊機封邊膠線的處理

Processing of Edge Bonding Adhesive Line for Fully Automatic Edge Bonding Machine

封邊后板材與封邊帶之間的膠線會對板式家具的外觀產生不良影響。涂膠量過大,會使膠線明顯,反之,又會降低封邊強度。對于不連續或不均勻的膠線現象,產生的原因是多方面的,要綜合考慮以下幾個因素:板材的開料精度,板材的邊一定要與它的平面保持90°角;封邊機壓輥的壓力是否分布均勻、大小合適,壓力方向要與板材邊成90°角;涂膠輥是否完好,熱熔膠在它上面是否均勻,涂膠量是否合適;封好邊的板材盡量保存在較為清潔,粉塵少的地方,在整理工序中,避免臟的東西與膠線接觸。

The adhesive line between the board and the edge banding strip after edge banding can have a negative impact on the appearance of panel furniture. Excessive adhesive application will make the adhesive line obvious, and conversely, it will reduce the edge sealing strength. For discontinuous or uneven adhesive lines, the reasons for their occurrence are multifaceted, and the following factors should be comprehensively considered: the cutting accuracy of the sheet metal, and the edges of the sheet metal must maintain a 90 ° angle with its plane; Is the pressure distribution of the edge banding machine pressure roller uniform and appropriate, and the pressure direction should be at a 90 ° angle with the edge of the sheet metal; Whether the gluing roller is intact, whether the hot melt adhesive is evenly applied on it, and whether the amount of glue applied is appropriate; The sealed edges of the board should be stored in a relatively clean and dust-free area as much as possible. During the sorting process, avoid contact between dirty objects and the adhesive line.

本文的精彩內容由全自動封膠線提供知識提供,本網站還有很多的精彩內容,更多的內容您可以點擊進入:http://www.yalais.com我們有專門的客服為您解答問題

The exciting content of this article is provided by the knowledge provided by the fully automatic sealing line. There are also many exciting content on this website, and you can click to enter more content: http://www.yalais.com We have dedicated customer service to answer your questions

上一篇:雙道密封鋁隔條式中空玻璃制作標準

下一篇:中空玻璃鋁條的作用介紹

相關新聞 more+

- 中空玻璃打膠機,助您開啟高效生產新時代! 2026/02/19

- 中空玻璃生產線打膠機傳送V帶不平衡?這樣調,傳送平穩不跑偏 2026/02/13

- 中空玻璃生產線打膠難題:壓力夠卻打不滿膠?這樣排查就解決 2026/02/12

- 全自動封膠線實操科普:山東昌盛板壓段,筑牢封膠質量核心防線 2026/02/10

- 中空玻璃生產線實操科普:小玻璃清洗機反轉打滾?這樣解決最省心 2026/02/06

- 全自動封膠線實操科普:白膠泵密封圈這樣換,杜絕漏膠保順暢 2026/02/04

- 雙組份打膠機實操科普:出膠體這樣保養維護,延長壽命保順暢 2026/02/02

- 中空玻璃生產線:清洗機這樣保養,清潔高效更耐用 2026/01/30

- 全自動封膠線實操科普:板壓壓合效果差?四角落差這樣調精準 2026/01/28

- 雙組份打膠機實操科普:黑膠泵過濾這樣清洗,避免堵塞保順暢 2026/01/27

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us