中空玻璃的生產流程

時間:2024-05-07 來源:http://www.yalais.com/ 發布人:昌盛機械

中空玻璃的生產流程

The production process of insulating glass

中空玻璃的生產流程大致如下:

The production process of insulating glass is roughly as follows:

1.玻璃切割。將原始玻璃按照設計要求切割成適當大小的塊狀,這通常通過自動化設備完成,以提高效率和減少人工失誤。

1. Glass cutting. Cutting the original glass into appropriately sized blocks according to design requirements is usually done through automated equipment to improve efficiency and reduce manual errors.

2.玻璃清洗。切割好的玻璃塊經過清洗工序,去除表面的污垢、油脂等雜質,以保證接下來的工序能夠順利進行,清洗通常使用高效的清洗機器,以確保在短時間內完成大批量玻璃的清洗。

2. Glass cleaning. The cut glass blocks undergo a cleaning process to remove impurities such as dirt and grease from the surface, ensuring the smooth progress of the subsequent process. Efficient cleaning machines are usually used to ensure the completion of large-scale glass cleaning in a short period of time.

3.質量檢測。清洗后的玻璃塊需要經過嚴格的質量檢測,以確保其符合標準和要求,檢測工序通常通過光學或機械設備來進行,可以檢測玻璃的平整度、厚度、表面缺陷等。

3. Quality inspection. The cleaned glass blocks need to undergo strict quality testing to ensure they meet standards and requirements. The testing process is usually carried out through optical or mechanical equipment, which can detect the flatness, thickness, surface defects, etc. of the glass.

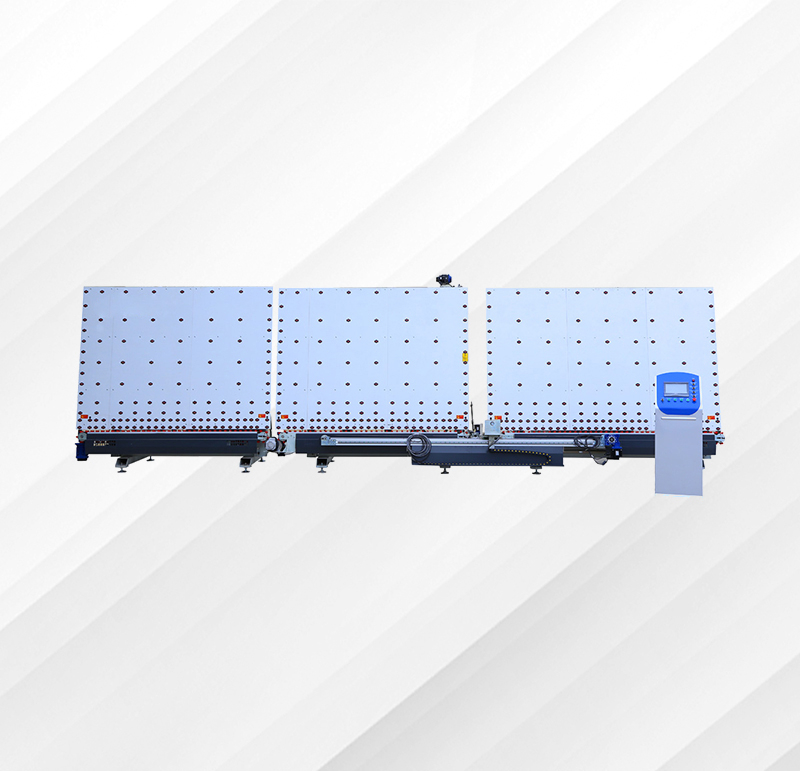

4.組裝。合格的玻璃塊被送入中空玻璃機器進行組裝,中空玻璃機器會自動將兩片或多片玻璃按照需要的間隔距離放置,并在玻璃邊緣周圍涂布密封膠條。

4. Assembly. Qualified glass blocks are fed into a hollow glass machine for assembly. The hollow glass machine will automatically place two or more pieces of glass at the required spacing and apply sealant strips around the edges of the glass.

5.密封。組裝好的玻璃經過密封工序,確保中空層的氣體或空氣不泄漏,密封一般采用高效的密封技術,如熱融膠或結構膠等。

5. Sealing. The assembled glass undergoes a sealing process to ensure that the gas or air in the hollow layer does not leak. Efficient sealing techniques such as hot melt adhesive or structural adhesive are generally used for sealing.

再次檢驗。最后,中空玻璃通過再次檢驗確保質量和性能達到要求,例如,可以進行玻璃外觀檢查、密封性測試、熱性能測試等。

Verify again. Finally, the quality and performance of the hollow glass are ensured to meet the requirements through re inspection, for example, glass appearance inspection, sealing test, thermal performance test, etc. can be carried out.

此外,生產中空玻璃時還需注意對環境的控制,包括溫度和相對濕度的調節,以及對干燥劑的選擇和使用,這些因素都會影響最終產品的質量。

In addition, when producing insulating glass, attention should also be paid to environmental control, including temperature and relative humidity adjustment, as well as the selection and use of desiccants, which will affect the quality of the final product.

本文由中空玻璃生產線友情奉獻。更多有關的知識請點 擊:http://www.yalais.com/真誠的態度為您提供為的服務,更多有關的知識我 們將會陸續向大家奉獻,敬請期待。

- 中空玻璃打膠機,助您開啟高效生產新時代! 2026/02/19

- 中空玻璃生產線打膠機傳送V帶不平衡?這樣調,傳送平穩不跑偏 2026/02/13

- 中空玻璃生產線打膠難題:壓力夠卻打不滿膠?這樣排查就解決 2026/02/12

- 全自動封膠線實操科普:山東昌盛板壓段,筑牢封膠質量核心防線 2026/02/10

- 中空玻璃生產線實操科普:小玻璃清洗機反轉打滾?這樣解決最省心 2026/02/06

- 全自動封膠線實操科普:白膠泵密封圈這樣換,杜絕漏膠保順暢 2026/02/04

- 雙組份打膠機實操科普:出膠體這樣保養維護,延長壽命保順暢 2026/02/02

- 中空玻璃生產線:清洗機這樣保養,清潔高效更耐用 2026/01/30

- 全自動封膠線實操科普:板壓壓合效果差?四角落差這樣調精準 2026/01/28

- 雙組份打膠機實操科普:黑膠泵過濾這樣清洗,避免堵塞保順暢 2026/01/27

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us