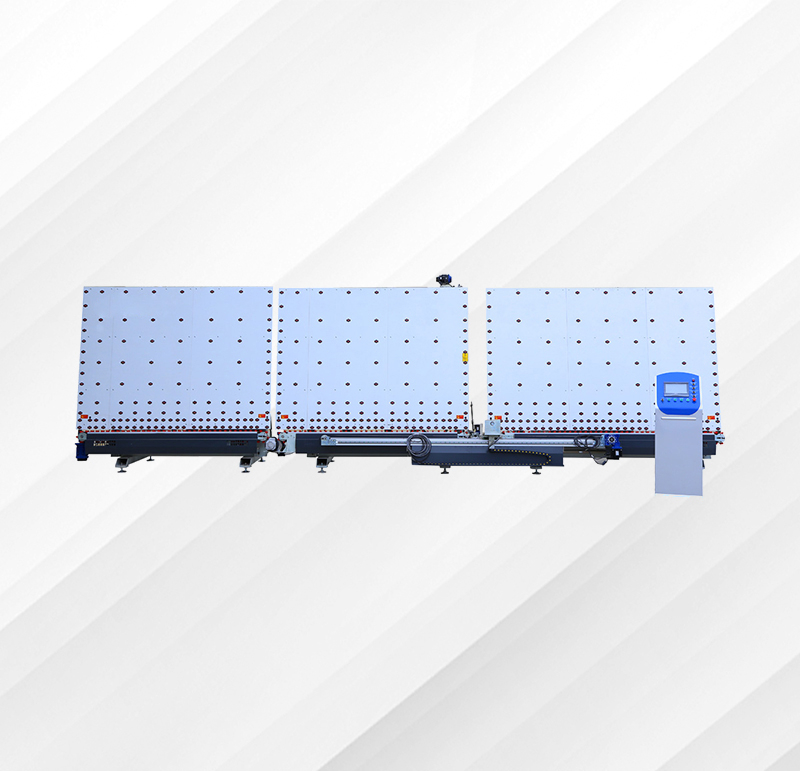

中空玻璃丁基膠涂布機(jī)漏油怎么解決

時(shí)間:2025-10-28 來源:http://www.yalais.com/ 發(fā)布人:昌盛機(jī)械

丁基膠涂布機(jī)漏油的解決方法

Solution to oil leakage of butyl rubber coating machine

1. 檢查并更換失效的密封件

1. Check and replace failed seals (the most common cause)

丁基膠涂布機(jī)的液壓系統(tǒng)(如油缸、高壓油管連接處)、膠頭加熱系統(tǒng)等多采用組合墊、O型密封圈等密封元件。若這些部件老化、損壞或安裝不當(dāng),易導(dǎo)致漏油。需定期檢查密封件狀態(tài),發(fā)現(xiàn)失效后及時(shí)更換:

The hydraulic system of butyl rubber coating machine (such as oil cylinder, high-pressure oil pipe connection), rubber head heating system, etc. often use combination gaskets, O-rings and other sealing components. If these components age, are damaged, or installed improperly, it can easily lead to oil leakage. Regularly check the condition of the seals and replace them promptly if any failure is found

更換前需停機(jī)斷電,拆掉舊密封件(注意避免劃傷接觸面);

Before replacement, the machine should be shut down and the power should be cut off. Remove the old seal (be careful not to scratch the contact surface);

用清潔劑(如家用清潔劑與水的混合溶液)徹底擦拭密封區(qū)域,頑固污漬可用礦物油精輔助清理;

Thoroughly wipe the sealed area with a cleaning agent (such as a mixture of household cleaning agent and water), and stubborn stains can be cleaned with mineral oil powder as an aid;

安裝新密封件時(shí),確保方向正確(如O型圈需順著油液流動(dòng)方向),貼合平整,避免扭曲或拉伸。

When installing new seals, ensure that the direction is correct (such as the O-ring should follow the direction of oil flow), the fit is flat, and avoid twisting or stretching.

2. 緊固松動(dòng)的連接部件

2. Tighten loose connecting components

液壓系統(tǒng)的高壓油管、法蘭等連接部位若松動(dòng),會(huì)導(dǎo)致油液滲漏。需定期檢查所有連接螺栓、卡箍的緊固情況,用扳手適當(dāng)擰緊(避免過度用力損壞部件),確保連接緊密。

If the high-pressure oil pipes, flanges, and other connecting parts of the hydraulic system become loose, it can cause oil leakage. Regularly check the tightness of all connecting bolts and clamps, and tighten them appropriately with a wrench (to avoid damaging components with excessive force) to ensure a tight connection.

3. 維護(hù)液壓系統(tǒng),避免壓力異常

3. Maintain the hydraulic system to avoid abnormal pressure

液壓壓力過高會(huì)增加密封件負(fù)荷,加速磨損導(dǎo)致漏油;壓力過低則可能導(dǎo)致油液竄漏。需定期檢查液壓站的壓力表,確保打膠過程中壓力穩(wěn)定在設(shè)計(jì)范圍內(nèi)(通常為10-20MPa,具體以設(shè)備說明書為準(zhǔn))。若壓力波動(dòng)較大,需排查液壓泵、溢流閥等部件是否故障。

Excessive hydraulic pressure can increase the load on seals, accelerate wear, and lead to oil leakage; If the pressure is too low, it may cause oil leakage. Regularly check the pressure gauge of the hydraulic station to ensure that the pressure remains stable within the design range (usually 10-20MPa, refer to the equipment manual for details) during the gluing process. If the pressure fluctuates greatly, it is necessary to check whether the hydraulic pump, relief valve and other components are faulty.

4. 清理油路與回油通道

4. Clean the oil circuit and return passage

液壓站的油箱、管路或回油孔若堵塞,會(huì)導(dǎo)致回油不暢,油液溢出。需定期清理油箱內(nèi)的雜質(zhì)(如膠渣、金屬顆粒),檢查回油孔是否被異物堵塞(如丁基膠殘留),必要時(shí)用煤油或?qū)S们逑磩┦柰ā?/p>

If the oil tank, pipeline or return hole of the hydraulic station is blocked, it will cause poor oil return and oil overflow. It is necessary to regularly clean the impurities (such as rubber residue and metal particles) in the fuel tank, check whether the oil return hole is blocked by foreign objects (such as residual butyl rubber), and if necessary, use kerosene or specialized cleaning agents to clear it.

5. 修復(fù)機(jī)體缺陷

5. Repair body defects

若設(shè)備機(jī)體存在砂眼、氣孔等鑄造缺陷,需采用焊接或焊補(bǔ)方式修復(fù)(如用不銹鋼焊條修補(bǔ)小砂眼),防止油液從缺陷處滲漏。修復(fù)后需打磨平整,避免劃傷密封件。

If there are casting defects such as sand holes and air holes in the equipment body, welding or welding repair methods (such as using stainless steel welding rods to repair small sand holes) should be used to prevent oil leakage from the defect. After repair, it needs to be polished flat to avoid scratching the sealing components.

6. 加強(qiáng)日常維護(hù)與巡檢

6. Strengthen daily maintenance and inspection

建立定期維護(hù)制度,每天開機(jī)前檢查設(shè)備外觀是否有油跡,每周檢查密封件、連接部件的狀態(tài),每月清理液壓系統(tǒng)和油路。通過“勤查、勤問、勤治”的方式,提前發(fā)現(xiàn)漏油隱患并及時(shí)處理。

Establish a regular maintenance system, check the appearance of the equipment for oil stains before starting up every day, inspect the condition of seals and connecting components every week, and clean the hydraulic system and oil circuit every month. Through the methods of "diligent inspection, diligent inquiry, and diligent treatment", oil leakage hazards can be detected in advance and dealt with in a timely manner.

本文由 中空玻璃丁基膠涂布機(jī) 友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊 http://www.yalais.com/ 真誠的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is a friendly contribution from the hollow glass butyl rubber coating machine For more related knowledge, please click http://www.yalais.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.丁基膠涂布機(jī)漏油的解決方法

Solution to oil leakage of butyl rubber coating machine

1. 檢查并更換失效的密封件(最常見原因)

1. Check and replace failed seals (the most common cause)

丁基膠涂布機(jī)的液壓系統(tǒng)(如油缸、高壓油管連接處)、膠頭加熱系統(tǒng)等多采用組合墊、O型密封圈等密封元件。若這些部件老化、損壞或安裝不當(dāng),易導(dǎo)致漏油。需定期檢查密封件狀態(tài),發(fā)現(xiàn)失效后及時(shí)更換:

The hydraulic system of butyl rubber coating machine (such as oil cylinder, high-pressure oil pipe connection), rubber head heating system, etc. often use combination gaskets, O-rings and other sealing components. If these components age, are damaged, or installed improperly, it can easily lead to oil leakage. Regularly check the condition of the seals and replace them promptly if any failure is found

更換前需停機(jī)斷電,拆掉舊密封件(注意避免劃傷接觸面);

Before replacement, the machine should be shut down and the power should be cut off. Remove the old seal (be careful not to scratch the contact surface);

用清潔劑(如家用清潔劑與水的混合溶液)徹底擦拭密封區(qū)域,頑固污漬可用礦物油精輔助清理;

Thoroughly wipe the sealed area with a cleaning agent (such as a mixture of household cleaning agent and water), and stubborn stains can be cleaned with mineral oil powder as an aid;

安裝新密封件時(shí),確保方向正確(如O型圈需順著油液流動(dòng)方向),貼合平整,避免扭曲或拉伸。

When installing new seals, ensure that the direction is correct (such as the O-ring should follow the direction of oil flow), the fit is flat, and avoid twisting or stretching.

2. 緊固松動(dòng)的連接部件

2. Tighten loose connecting components

液壓系統(tǒng)的高壓油管、法蘭等連接部位若松動(dòng),會(huì)導(dǎo)致油液滲漏。需定期檢查所有連接螺栓、卡箍的緊固情況,用扳手適當(dāng)擰緊(避免過度用力損壞部件),確保連接緊密。

If the high-pressure oil pipes, flanges, and other connecting parts of the hydraulic system become loose, it can cause oil leakage. Regularly check the tightness of all connecting bolts and clamps, and tighten them appropriately with a wrench (to avoid damaging components with excessive force) to ensure a tight connection.

3. 維護(hù)液壓系統(tǒng),避免壓力異常

3. Maintain the hydraulic system to avoid abnormal pressure

液壓壓力過高會(huì)增加密封件負(fù)荷,加速磨損導(dǎo)致漏油;壓力過低則可能導(dǎo)致油液竄漏。需定期檢查液壓站的壓力表,確保打膠過程中壓力穩(wěn)定在設(shè)計(jì)范圍內(nèi)(通常為10-20MPa,具體以設(shè)備說明書為準(zhǔn))。若壓力波動(dòng)較大,需排查液壓泵、溢流閥等部件是否故障。

Excessive hydraulic pressure can increase the load on seals, accelerate wear, and lead to oil leakage; If the pressure is too low, it may cause oil leakage. Regularly check the pressure gauge of the hydraulic station to ensure that the pressure remains stable within the design range (usually 10-20MPa, refer to the equipment manual for details) during the gluing process. If the pressure fluctuates greatly, it is necessary to check whether the hydraulic pump, relief valve and other components are faulty.

4. 清理油路與回油通道

4. Clean the oil circuit and return passage

液壓站的油箱、管路或回油孔若堵塞,會(huì)導(dǎo)致回油不暢,油液溢出。需定期清理油箱內(nèi)的雜質(zhì)(如膠渣、金屬顆粒),檢查回油孔是否被異物堵塞(如丁基膠殘留),必要時(shí)用煤油或?qū)S们逑磩┦柰ā?/p>

If the oil tank, pipeline or return hole of the hydraulic station is blocked, it will cause poor oil return and oil overflow. It is necessary to regularly clean the impurities (such as rubber residue and metal particles) in the fuel tank, check whether the oil return hole is blocked by foreign objects (such as residual butyl rubber), and if necessary, use kerosene or specialized cleaning agents to clear it.

5. 修復(fù)機(jī)體缺陷

5. Repair body defects

若設(shè)備機(jī)體存在砂眼、氣孔等鑄造缺陷,需采用焊接或焊補(bǔ)方式修復(fù)(如用不銹鋼焊條修補(bǔ)小砂眼),防止油液從缺陷處滲漏。修復(fù)后需打磨平整,避免劃傷密封件。

If there are casting defects such as sand holes and air holes in the equipment body, welding or welding repair methods (such as using stainless steel welding rods to repair small sand holes) should be used to prevent oil leakage from the defect. After repair, it needs to be polished flat to avoid scratching the sealing components.

6. 加強(qiáng)日常維護(hù)與巡檢

6. Strengthen daily maintenance and inspection

建立定期維護(hù)制度,每天開機(jī)前檢查設(shè)備外觀是否有油跡,每周檢查密封件、連接部件的狀態(tài),每月清理液壓系統(tǒng)和油路。通過“勤查、勤問、勤治”的方式,提前發(fā)現(xiàn)漏油隱患并及時(shí)處理。

Establish a regular maintenance system, check the appearance of the equipment for oil stains before starting up every day, inspect the condition of seals and connecting components every week, and clean the hydraulic system and oil circuit every month. Through the methods of "diligent inspection, diligent inquiry, and diligent treatment", oil leakage hazards can be detected in advance and dealt with in a timely manner.

本文由 中空玻璃丁基膠涂布機(jī) 友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊 http://www.yalais.com/ 真誠的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is a friendly contribution from the hollow glass butyl rubber coating machine For more related knowledge, please click http://www.yalais.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon. 丁基膠涂布機(jī)漏油的解決方法

Solution to oil leakage of butyl rubber coating machine

1. 檢查并更換失效的密封件(最常見原因)

1. Check and replace failed seals (the most common cause)

丁基膠涂布機(jī)的液壓系統(tǒng)(如油缸、高壓油管連接處)、膠頭加熱系統(tǒng)等多采用組合墊、O型密封圈等密封元件。若這些部件老化、損壞或安裝不當(dāng),易導(dǎo)致漏油。需定期檢查密封件狀態(tài),發(fā)現(xiàn)失效后及時(shí)更換:

The hydraulic system of butyl rubber coating machine (such as oil cylinder, high-pressure oil pipe connection), rubber head heating system, etc. often use combination gaskets, O-rings and other sealing components. If these components age, are damaged, or installed improperly, it can easily lead to oil leakage. Regularly check the condition of the seals and replace them promptly if any failure is found

更換前需停機(jī)斷電,拆掉舊密封件(注意避免劃傷接觸面);

Before replacement, the machine should be shut down and the power should be cut off. Remove the old seal (be careful not to scratch the contact surface);

用清潔劑(如家用清潔劑與水的混合溶液)徹底擦拭密封區(qū)域,頑固污漬可用礦物油精輔助清理;

Thoroughly wipe the sealed area with a cleaning agent (such as a mixture of household cleaning agent and water), and stubborn stains can be cleaned with mineral oil powder as an aid;

安裝新密封件時(shí),確保方向正確(如O型圈需順著油液流動(dòng)方向),貼合平整,避免扭曲或拉伸。

When installing new seals, ensure that the direction is correct (such as the O-ring should follow the direction of oil flow), the fit is flat, and avoid twisting or stretching.

2. 緊固松動(dòng)的連接部件

2. Tighten loose connecting components

液壓系統(tǒng)的高壓油管、法蘭等連接部位若松動(dòng),會(huì)導(dǎo)致油液滲漏。需定期檢查所有連接螺栓、卡箍的緊固情況,用扳手適當(dāng)擰緊(避免過度用力損壞部件),確保連接緊密。

If the high-pressure oil pipes, flanges, and other connecting parts of the hydraulic system become loose, it can cause oil leakage. Regularly check the tightness of all connecting bolts and clamps, and tighten them appropriately with a wrench (to avoid damaging components with excessive force) to ensure a tight connection.

3. 維護(hù)液壓系統(tǒng),避免壓力異常

3. Maintain the hydraulic system to avoid abnormal pressure

液壓壓力過高會(huì)增加密封件負(fù)荷,加速磨損導(dǎo)致漏油;壓力過低則可能導(dǎo)致油液竄漏。需定期檢查液壓站的壓力表,確保打膠過程中壓力穩(wěn)定在設(shè)計(jì)范圍內(nèi)(通常為10-20MPa,具體以設(shè)備說明書為準(zhǔn))。若壓力波動(dòng)較大,需排查液壓泵、溢流閥等部件是否故障。

Excessive hydraulic pressure can increase the load on seals, accelerate wear, and lead to oil leakage; If the pressure is too low, it may cause oil leakage. Regularly check the pressure gauge of the hydraulic station to ensure that the pressure remains stable within the design range (usually 10-20MPa, refer to the equipment manual for details) during the gluing process. If the pressure fluctuates greatly, it is necessary to check whether the hydraulic pump, relief valve and other components are faulty.

4. 清理油路與回油通道

4. Clean the oil circuit and return passage

液壓站的油箱、管路或回油孔若堵塞,會(huì)導(dǎo)致回油不暢,油液溢出。需定期清理油箱內(nèi)的雜質(zhì)(如膠渣、金屬顆粒),檢查回油孔是否被異物堵塞(如丁基膠殘留),必要時(shí)用煤油或?qū)S们逑磩┦柰ā?/p>

If the oil tank, pipeline or return hole of the hydraulic station is blocked, it will cause poor oil return and oil overflow. It is necessary to regularly clean the impurities (such as rubber residue and metal particles) in the fuel tank, check whether the oil return hole is blocked by foreign objects (such as residual butyl rubber), and if necessary, use kerosene or specialized cleaning agents to clear it.

5. 修復(fù)機(jī)體缺陷

5. Repair body defects

若設(shè)備機(jī)體存在砂眼、氣孔等鑄造缺陷,需采用焊接或焊補(bǔ)方式修復(fù)(如用不銹鋼焊條修補(bǔ)小砂眼),防止油液從缺陷處滲漏。修復(fù)后需打磨平整,避免劃傷密封件。

If there are casting defects such as sand holes and air holes in the equipment body, welding or welding repair methods (such as using stainless steel welding rods to repair small sand holes) should be used to prevent oil leakage from the defect. After repair, it needs to be polished flat to avoid scratching the sealing components.

6. 加強(qiáng)日常維護(hù)與巡檢

6. Strengthen daily maintenance and inspection

建立定期維護(hù)制度,每天開機(jī)前檢查設(shè)備外觀是否有油跡,每周檢查密封件、連接部件的狀態(tài),每月清理液壓系統(tǒng)和油路。通過“勤查、勤問、勤治”的方式,提前發(fā)現(xiàn)漏油隱患并及時(shí)處理。

Establish a regular maintenance system, check the appearance of the equipment for oil stains before starting up every day, inspect the condition of seals and connecting components every week, and clean the hydraulic system and oil circuit every month. Through the methods of "diligent inspection, diligent inquiry, and diligent treatment", oil leakage hazards can be detected in advance and dealt with in a timely manner.

本文由 中空玻璃丁基膠涂布機(jī) 友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊 http://www.yalais.com/ 真誠的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is a friendly contribution from the hollow glass butyl rubber coating machine For more related knowledge, please click http://www.yalais.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.丁基膠涂布機(jī)漏油的解決方法

Solution to oil leakage of butyl rubber coating machine

1. 檢查并更換失效的密封件(最常見原因)

1. Check and replace failed seals (the most common cause)

丁基膠涂布機(jī)的液壓系統(tǒng)(如油缸、高壓油管連接處)、膠頭加熱系統(tǒng)等多采用組合墊、O型密封圈等密封元件。若這些部件老化、損壞或安裝不當(dāng),易導(dǎo)致漏油。需定期檢查密封件狀態(tài),發(fā)現(xiàn)失效后及時(shí)更換:

The hydraulic system of butyl rubber coating machine (such as oil cylinder, high-pressure oil pipe connection), rubber head heating system, etc. often use combination gaskets, O-rings and other sealing components. If these components age, are damaged, or installed improperly, it can easily lead to oil leakage. Regularly check the condition of the seals and replace them promptly if any failure is found

更換前需停機(jī)斷電,拆掉舊密封件(注意避免劃傷接觸面);

Before replacement, the machine should be shut down and the power should be cut off. Remove the old seal (be careful not to scratch the contact surface);

用清潔劑(如家用清潔劑與水的混合溶液)徹底擦拭密封區(qū)域,頑固污漬可用礦物油精輔助清理;

Thoroughly wipe the sealed area with a cleaning agent (such as a mixture of household cleaning agent and water), and stubborn stains can be cleaned with mineral oil powder as an aid;

安裝新密封件時(shí),確保方向正確(如O型圈需順著油液流動(dòng)方向),貼合平整,避免扭曲或拉伸。

When installing new seals, ensure that the direction is correct (such as the O-ring should follow the direction of oil flow), the fit is flat, and avoid twisting or stretching.

2. 緊固松動(dòng)的連接部件

2. Tighten loose connecting components

液壓系統(tǒng)的高壓油管、法蘭等連接部位若松動(dòng),會(huì)導(dǎo)致油液滲漏。需定期檢查所有連接螺栓、卡箍的緊固情況,用扳手適當(dāng)擰緊(避免過度用力損壞部件),確保連接緊密。

If the high-pressure oil pipes, flanges, and other connecting parts of the hydraulic system become loose, it can cause oil leakage. Regularly check the tightness of all connecting bolts and clamps, and tighten them appropriately with a wrench (to avoid damaging components with excessive force) to ensure a tight connection.

3. 維護(hù)液壓系統(tǒng),避免壓力異常

3. Maintain the hydraulic system to avoid abnormal pressure

液壓壓力過高會(huì)增加密封件負(fù)荷,加速磨損導(dǎo)致漏油;壓力過低則可能導(dǎo)致油液竄漏。需定期檢查液壓站的壓力表,確保打膠過程中壓力穩(wěn)定在設(shè)計(jì)范圍內(nèi)(通常為10-20MPa,具體以設(shè)備說明書為準(zhǔn))。若壓力波動(dòng)較大,需排查液壓泵、溢流閥等部件是否故障。

Excessive hydraulic pressure can increase the load on seals, accelerate wear, and lead to oil leakage; If the pressure is too low, it may cause oil leakage. Regularly check the pressure gauge of the hydraulic station to ensure that the pressure remains stable within the design range (usually 10-20MPa, refer to the equipment manual for details) during the gluing process. If the pressure fluctuates greatly, it is necessary to check whether the hydraulic pump, relief valve and other components are faulty.

4. 清理油路與回油通道

4. Clean the oil circuit and return passage

液壓站的油箱、管路或回油孔若堵塞,會(huì)導(dǎo)致回油不暢,油液溢出。需定期清理油箱內(nèi)的雜質(zhì)(如膠渣、金屬顆粒),檢查回油孔是否被異物堵塞(如丁基膠殘留),必要時(shí)用煤油或?qū)S们逑磩┦柰ā?/p>

If the oil tank, pipeline or return hole of the hydraulic station is blocked, it will cause poor oil return and oil overflow. It is necessary to regularly clean the impurities (such as rubber residue and metal particles) in the fuel tank, check whether the oil return hole is blocked by foreign objects (such as residual butyl rubber), and if necessary, use kerosene or specialized cleaning agents to clear it.

5. 修復(fù)機(jī)體缺陷

5. Repair body defects

若設(shè)備機(jī)體存在砂眼、氣孔等鑄造缺陷,需采用焊接或焊補(bǔ)方式修復(fù)(如用不銹鋼焊條修補(bǔ)小砂眼),防止油液從缺陷處滲漏。修復(fù)后需打磨平整,避免劃傷密封件。

If there are casting defects such as sand holes and air holes in the equipment body, welding or welding repair methods (such as using stainless steel welding rods to repair small sand holes) should be used to prevent oil leakage from the defect. After repair, it needs to be polished flat to avoid scratching the sealing components.

6. 加強(qiáng)日常維護(hù)與巡檢

6. Strengthen daily maintenance and inspection

建立定期維護(hù)制度,每天開機(jī)前檢查設(shè)備外觀是否有油跡,每周檢查密封件、連接部件的狀態(tài),每月清理液壓系統(tǒng)和油路。通過“勤查、勤問、勤治”的方式,提前發(fā)現(xiàn)漏油隱患并及時(shí)處理。

Establish a regular maintenance system, check the appearance of the equipment for oil stains before starting up every day, inspect the condition of seals and connecting components every week, and clean the hydraulic system and oil circuit every month. Through the methods of "diligent inspection, diligent inquiry, and diligent treatment", oil leakage hazards can be detected in advance and dealt with in a timely manner.

本文由 中空玻璃丁基膠涂布機(jī) 友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊 http://www.yalais.com/ 真誠的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is a friendly contribution from the hollow glass butyl rubber coating machine For more related knowledge, please click http://www.yalais.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 中空玻璃打膠機(jī),助您開啟高效生產(chǎn)新時(shí)代! 2026/02/19

- 中空玻璃生產(chǎn)線打膠機(jī)傳送V帶不平衡?這樣調(diào),傳送平穩(wěn)不跑偏 2026/02/13

- 中空玻璃生產(chǎn)線打膠難題:壓力夠卻打不滿膠?這樣排查就解決 2026/02/12

- 全自動(dòng)封膠線實(shí)操科普:山東昌盛板壓段,筑牢封膠質(zhì)量核心防線 2026/02/10

- 中空玻璃生產(chǎn)線實(shí)操科普:小玻璃清洗機(jī)反轉(zhuǎn)打滾?這樣解決最省心 2026/02/06

- 全自動(dòng)封膠線實(shí)操科普:白膠泵密封圈這樣換,杜絕漏膠保順暢 2026/02/04

- 雙組份打膠機(jī)實(shí)操科普:出膠體這樣保養(yǎng)維護(hù),延長壽命保順暢 2026/02/02

- 中空玻璃生產(chǎn)線:清洗機(jī)這樣保養(yǎng),清潔高效更耐用 2026/01/30

- 全自動(dòng)封膠線實(shí)操科普:板壓壓合效果差?四角落差這樣調(diào)精準(zhǔn) 2026/01/28

- 雙組份打膠機(jī)實(shí)操科普:黑膠泵過濾這樣清洗,避免堵塞保順暢 2026/01/27

產(chǎn)品分類Product categories

產(chǎn)品分類Product categories

聯(lián)系我們Contact us

聯(lián)系我們Contact us

- 咨詢熱線:0531-85717458 13705446998

- 公司地址: 山東省德州市齊河安頭鄉(xiāng)企巢工業(yè)園

- 掃碼聯(lián)系我們:

當(dāng)前位置:

當(dāng)前位置: