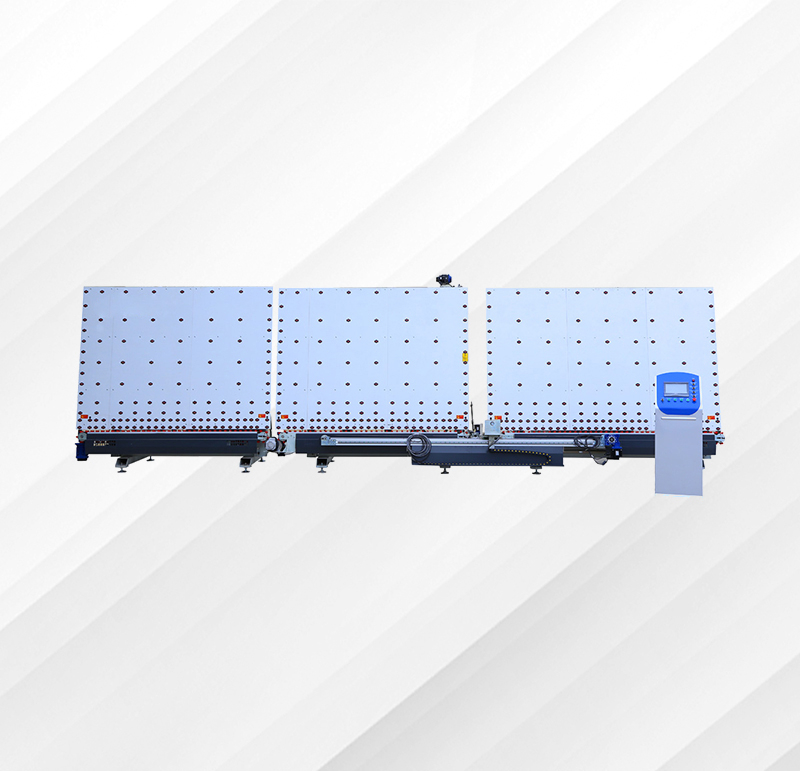

全自動丁基膠涂布機膠缸不進不退怎么解決?

時間:2025-11-22 來源:http://www.yalais.com/ 發布人:昌盛機械

丁基膠涂布機膠缸不進不退的常見原因及解決方法如下:

The common reasons and solutions for the rubber cylinder of the butyl rubber coating machine not moving in or out are as follows:

一、主要原因分析

1、 Main cause analysis

電磁閥故障

Electromagnetic valve malfunction

若壓力正常但膠缸不進不退,可能是電磁閥卡住或損壞,需維修或更換。

If the pressure is normal but the rubber cylinder does not move in or out, it may be due to the solenoid valve being stuck or damaged, and it needs to be repaired or replaced.

油缸內泄或堵塞

Leakage or blockage inside the oil cylinder

油缸內泄會導致壓力無法傳遞,需更換油缸;膠路或膠座堵塞也會阻礙膠缸正常工作。

Internal leakage of the oil cylinder will result in the inability to transmit pressure, and the oil cylinder needs to be replaced; Blockage of the rubber path or rubber seat can also hinder the normal operation of the rubber cylinder.

操作參數異常

Abnormal operation parameters

膠缸未完全退到位或未觸發微動開關,需檢查操作流程是否正確。

The rubber cylinder has not been fully retracted or the micro switch has not been triggered. It is necessary to check whether the operation process is correct.

氣壓設置過高(超過系統承受范圍),需調低氣壓。

The air pressure setting is too high (exceeding the system's tolerance range), and the air pressure needs to be lowered.

設備老化或維護不足

Equipment aging or insufficient maintenance

舊設備易出現機械故障,需定期維護或更換;膠頭螺距不當或膠嘴堵塞也會影響進退。

Old equipment is prone to mechanical failures and requires regular maintenance or replacement; Improper pitch of the rubber head or blockage of the rubber nozzle can also affect the advance and retreat.

二、解決方案

2、 Solution

檢查電磁閥狀態

Check the status of the solenoid valve

手動操作時觀察電磁閥是否正常工作,若卡住需立即維修或更換。

Observe whether the solenoid valve is working properly during manual operation. If it gets stuck, repair or replace it immediately.

排查油缸及膠路問題

Check for issues with the oil cylinder and rubber circuit

更換內泄油缸或密封件。

Replace the internal drain cylinder or seal.

清理膠路異物,檢查膠座開關軸位置是否正確。

Clean up foreign objects in the rubber path and check if the position of the rubber seat switch shaft is correct.

優化操作流程

Optimize the operational process

確保膠缸完全退到位并觸發微動開關,檢查氣壓是否在設定范圍內(通常0.7-2.0MPa)。

Ensure that the rubber cylinder is fully retracted and trigger the micro switch, and check if the air pressure is within the set range (usually 0.7-2.0MPa).

定期維護與設備更新

Regular maintenance and equipment updates

定期檢查設備磨損情況,及時更換老化部件;若頻繁故障,建議更換新設備。

Regularly check the wear and tear of equipment and replace aging components in a timely manner; If there are frequent malfunctions, it is recommended to replace the equipment with a new one.

三、注意事項

3、 Precautions

若問題持續且涉及高壓部件(如增壓泵),需聯系專業人員檢修。

If the problem persists and involves high-pressure components (such as booster pumps), it is necessary to contact professional personnel for maintenance.

操作時避免過度用力,防止損壞內部結構。

Avoid excessive force during operation to prevent damage to the internal structure.

本文由 全自動丁基膠涂布機 友情奉獻.更多有關的知識請點擊 http://www.yalais.com/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the fully automatic butyl rubber coating machine For more related knowledge, please click http://www.yalais.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 中空玻璃打膠機,助您開啟高效生產新時代! 2026/02/19

- 中空玻璃生產線打膠機傳送V帶不平衡?這樣調,傳送平穩不跑偏 2026/02/13

- 中空玻璃生產線打膠難題:壓力夠卻打不滿膠?這樣排查就解決 2026/02/12

- 全自動封膠線實操科普:山東昌盛板壓段,筑牢封膠質量核心防線 2026/02/10

- 中空玻璃生產線實操科普:小玻璃清洗機反轉打滾?這樣解決最省心 2026/02/06

- 全自動封膠線實操科普:白膠泵密封圈這樣換,杜絕漏膠保順暢 2026/02/04

- 雙組份打膠機實操科普:出膠體這樣保養維護,延長壽命保順暢 2026/02/02

- 中空玻璃生產線:清洗機這樣保養,清潔高效更耐用 2026/01/30

- 全自動封膠線實操科普:板壓壓合效果差?四角落差這樣調精準 2026/01/28

- 雙組份打膠機實操科普:黑膠泵過濾這樣清洗,避免堵塞保順暢 2026/01/27

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us