中空玻璃打膠總翻車?雙組份打膠機效果驚艷到離譜!

時間:2025-12-17 來源:http://www.yalais.com/ 發布人:昌盛機械

中空玻璃打膠總翻車?雙組份打膠機效果驚艷到離譜!

Does insulating glass always overturn when glued? The effect of the two-component glue machine is stunning and outrageous!

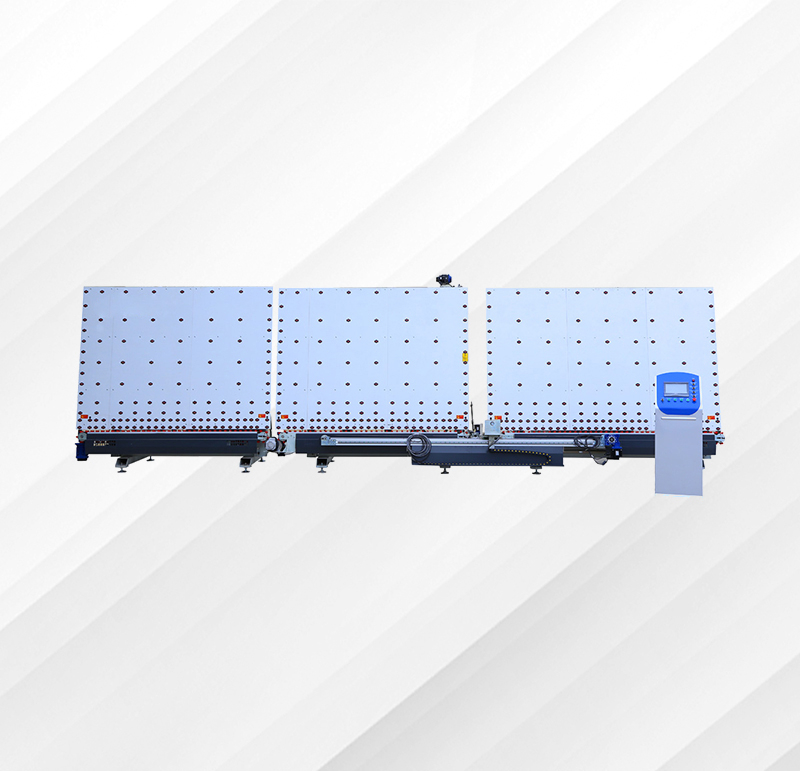

咱玻璃廠做中空玻璃,打膠環節真是“一言難盡”!以前靠人工打膠,純屬憑運氣——膠線歪歪扭扭像蛇爬,氣泡、斷點隨處可見,看著就鬧心;更糟的是后期返工,客戶反饋漏風漏水,拆下來一看,不是膠沒涂勻就是斷膠了,又費料又費工,工人累得夠嗆還沒產值。直到用上雙組份打膠機,才知道打膠能這么省心,配著中空玻璃生產線用,效率和品質直接拉滿,效果驚艷到離譜!

Our glass factory produces insulated glass, and the gluing process is really difficult to describe! In the past, manual gluing was purely based on luck - the glue line was crooked and twisted like a snake crawling, and bubbles and breakpoints could be seen everywhere, making it annoying to look at; Even worse, during the later stage of rework, customers reported air and water leaks. Upon dismantling, it was found that either the glue was not evenly applied or had broken, which was both material and labor intensive. The workers were exhausted and had no output value. It wasn't until I used a two-component gluing machine that I realized how easy it was to glue. When paired with an insulated glass production line, the efficiency and quality were directly maximized, and the effect was stunning beyond imagination!

先說說最讓人佩服的膠線均勻度,簡直是“零誤差”級別。不管是常規尺寸玻璃的直邊,還是異形玻璃的不規則邊緣,膠槍都能穩定出膠,涂出來的膠線粗細一致,像用尺子量過一樣標準,完全沒有人工打膠那種忽厚忽薄的情況。更難得的是,膠線里沒有一點氣泡、沒有一處斷點,緊緊貼在玻璃密封邊上,密封性能直接達標,后期根本不用再補膠修膠,客戶驗收一次就能過。

First, let's talk about the most impressive uniformity of the glue line, which is truly at the "zero error" level. Whether it is the straight edges of regular sized glass or the irregular edges of irregular shaped glass, the glue gun can stably produce glue, and the thickness of the glue line applied is consistent, as if measured with a ruler, without the sudden thickness and thinness of manual glue. What's even more rare is that there are no bubbles or breakpoints in the glue line, which is tightly attached to the glass sealing edge, and the sealing performance meets the standard directly. There is no need to repair the glue in the later stage, and the customer can pass the inspection once.

定位精準度也絕了,完全不溢膠、不漏膠。設備自帶數控定位系統,就像長了“火眼金睛”,能精準識別玻璃的密封邊位置,膠槍沿著邊緣勻速打膠,膠線剛好卡在該在的地方——不往玻璃表面溢膠,不用后期額外擦膠;也不往鋁條里漏膠,既省了丁基膠、密封膠這些耗材,成品玻璃還干凈美觀,看著就專業。以前人工打膠,溢膠是常事,刮掉的都是錢,長期下來浪費不少,現在有了這臺設備,耗材成本都降了一截。

The positioning accuracy is also unparalleled, with no glue overflow or leakage at all. The device comes with a built-in CNC positioning system, which is like having a "golden eye" that can accurately identify the position of the sealing edge of the glass. The glue gun applies glue at a constant speed along the edge, and the glue line is stuck exactly where it should be - without overflowing glue onto the surface of the glass and without the need for additional wiping later on; It also does not leak glue into the aluminum strip, saving consumables such as butyl rubber and sealant. The finished glass is clean and beautiful, and looks professional. In the past, manual gluing and glue overflow were common occurrences, and all that was scraped off was money, which wasted a lot in the long run. Now with this equipment, the cost of consumables has been reduced significantly.

最讓人驚喜的是拐角打膠,順滑到難以置信。做中空玻璃難免遇到直角、圓角,以前人工打膠,拐角處要么膠堆積成疙瘩,要么斷檔留縫隙,密封效果大打折扣。雙組份打膠機遇到拐角時,會自動調整打膠速度和角度,膠線轉彎處銜接得嚴絲合縫,沒有一點堆積,也沒有一絲斷檔,比有十幾年經驗的老工人手工打膠還精致,完全不影響玻璃的整體密封性能。

The most surprising thing is the corner gluing, which is incredibly smooth. When making insulated glass, it is inevitable to encounter right angles and rounded corners. In the past, manual glue was applied, and the corners either accumulated into lumps or left gaps, greatly reducing the sealing effect. When the two-component gluing machine encounters a corner, it will automatically adjust the gluing speed and angle. The glue line is seamlessly connected at the turning point, without any accumulation or interruption. It is more exquisite than manual gluing by experienced workers with more than ten years of experience, and does not affect the overall sealing performance of the glass.

而且它能跟中空玻璃生產線無縫銜接,批量生產效果穩如定海神針。玻璃從合片環節送過來,直接進入打膠工序,不用工人中途搬運、等待,設備自動抓取、自動定位、自動打膠,打完膠直接送往下一環節,整條生產線效率翻倍。更重要的是,每一塊玻璃的打膠效果都一模一樣,不會出現“這塊好那塊差”的情況,就算是一天幾千塊的批量訂單,也能保證品質統一,返工率近乎零。

And it can seamlessly connect with the insulated glass production line, and the mass production effect is as stable as a sea needle. The glass is sent from the lamination process and directly enters the gluing process, without the need for workers to handle or wait halfway. The equipment automatically grasps, locates, and glues, and after gluing, it is directly sent to the next process, doubling the efficiency of the entire production line. More importantly, the gluing effect of each piece of glass is the same, and there will be no "one piece is good and the other piece is bad". Even if the batch order is thousands of pieces a day, the quality can be guaranteed to be uniform, and the rework rate is almost zero.

以前3個人一天累死累活打200塊玻璃還總出錯,現在1臺雙組份打膠機就能頂3個人,不僅效率高,效果還比人工好10倍。操作也簡單,工人只要在面板上設置好參數,一鍵啟動就行,不用專門養技術工,省了不少人工成本。對于玻璃廠來說,這可不是小好處,既提升了產能,又穩住了品質,還降低了成本,簡直是打膠環節的“神器”。

Previously, three people worked tirelessly to make 200 pieces of glass in a day and always made mistakes. Now, one two-component gluing machine can support three people, which is not only efficient but also 10 times better than manual labor. The operation is also simple. Workers only need to set the parameters on the panel and start with one click, without the need for specialized technicians, saving a lot of labor costs. For glass factories, this is not a small benefit, as it not only increases production capacity, stabilizes quality, but also reduces costs. It is simply a "miracle tool" in the gluing process.

現在玻璃行業競爭這么卷,客戶對品質的要求越來越高,打膠這種關鍵環節可不能再翻車了。雙組份打膠機用實實在在的效果證明,打膠不用靠運氣,靠設備就能穩贏。不管你是做常規中空玻璃,還是異形、大尺寸的高端訂單,它都能輕松hold住,讓每一塊玻璃的密封都無懈可擊。

The competition in the glass industry is so fierce now, and customers have increasingly high requirements for quality. The key link of gluing cannot afford to fail again. The two-component gluing machine has proven with practical results that gluing does not rely on luck, but on equipment to win steadily. Whether you are making regular insulated glass or high-end orders with irregular or large-sized shapes, it can easily hold and ensure that the sealing of each piece of glass is impeccable.

想親眼看看它怎么給中空玻璃精準打膠?看看廠家的實拍視頻就知道,膠線均勻、拐角順滑、定位精準,每一步都讓人驚艷。如果你的玻璃廠還在被打膠翻車的問題困擾,不妨試試這臺雙組份打膠機,讓打膠環節從“煩心事”變成“放心事”!

Want to see with your own eyes how it accurately glues insulating glass? You can tell from the manufacturer's live action videos that the glue line is even, the corners are smooth, and the positioning is precise, every step is stunning. If your glass factory is still troubled by the problem of glue tipping over, you may want to try this two-component glue gluing machine, which can turn the gluing process from a "troublesome matter" to a "reassuring matter"!

本文由 雙組份打膠機 友情奉獻.更多有關的知識請點擊 http://www.jyslpg.com/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from a two-component glue machine For more related knowledge, please click http://www.jyslpg.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 中空玻璃打膠機,助您開啟高效生產新時代! 2026/02/19

- 中空玻璃生產線打膠機傳送V帶不平衡?這樣調,傳送平穩不跑偏 2026/02/13

- 中空玻璃生產線打膠難題:壓力夠卻打不滿膠?這樣排查就解決 2026/02/12

- 全自動封膠線實操科普:山東昌盛板壓段,筑牢封膠質量核心防線 2026/02/10

- 中空玻璃生產線實操科普:小玻璃清洗機反轉打滾?這樣解決最省心 2026/02/06

- 全自動封膠線實操科普:白膠泵密封圈這樣換,杜絕漏膠保順暢 2026/02/04

- 雙組份打膠機實操科普:出膠體這樣保養維護,延長壽命保順暢 2026/02/02

- 中空玻璃生產線:清洗機這樣保養,清潔高效更耐用 2026/01/30

- 全自動封膠線實操科普:板壓壓合效果差?四角落差這樣調精準 2026/01/28

- 雙組份打膠機實操科普:黑膠泵過濾這樣清洗,避免堵塞保順暢 2026/01/27

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us