冬天中空玻璃生產(chǎn)線出輪子灰印?這些日常難題解決辦法請收好

時間:2025-12-30 來源:http://www.yalais.com/ 發(fā)布人:昌盛機械

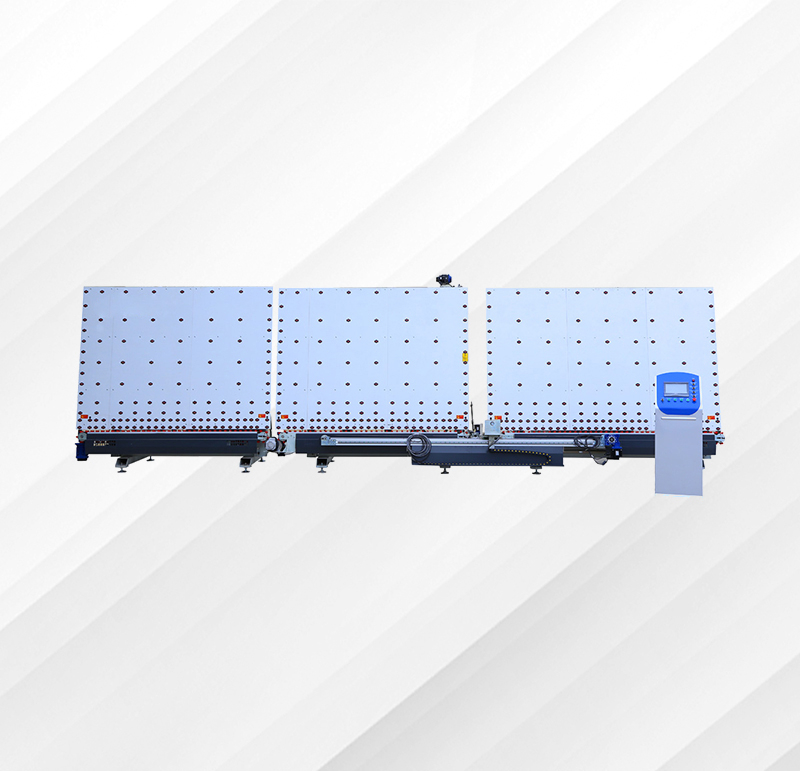

在中空玻璃生產(chǎn)過程中,日常操作里總會遇到各種小難題,尤其到了冬天,低溫環(huán)境下的設(shè)備運行問題更讓人頭疼。不少生產(chǎn)線操作人員都遇到過這樣的情況:冬天給生產(chǎn)線水加熱到38度后,玻璃從風機出來時,表面會留下明顯的輪子灰印。這不僅影響玻璃外觀質(zhì)量,還可能增加返工成本。今天就專門科普中空玻璃生產(chǎn)線的日常使用難題,重點說說這個冬天常見的輪子灰印問題,再分享實用的解決辦法。

In the production process of insulating glass, various small problems are always encountered in daily operations, especially in winter, when equipment operation problems in low-temperature environments are even more headache inducing. Many production line operators have encountered this situation: in winter, when the water on the production line is heated to 38 degrees, there will be obvious wheel dust marks on the surface of the glass when it comes out of the fan. This not only affects the appearance quality of the glass, but may also increase the cost of rework. Today, we will focus on the daily use problems of insulated glass production lines, with a particular emphasis on the common issue of wheel dust marks this winter, and then share practical solutions.

先說說冬天水加熱38度后出現(xiàn)輪子灰印的核心原因。一方面,冬天環(huán)境溫度低,生產(chǎn)線水加熱到38度后,會產(chǎn)生一定的水汽,這些水汽容易吸附空氣中的灰塵、粉塵,當玻璃在輸送輪子上移動時,水汽帶著灰塵就會附著在玻璃表面,形成灰印;另一方面,輸送輪子長期使用后,表面會積累油污、粉塵等雜質(zhì),冬天水汽多,這些雜質(zhì)更容易轉(zhuǎn)移到玻璃上,尤其是經(jīng)過風機吹風后,灰印會更明顯,難以清除。

Let's first talk about the core reason for wheel gray marks after heating water to 38 degrees in winter. On the one hand, in winter, the ambient temperature is low, and when the water in the production line is heated to 38 degrees, a certain amount of water vapor will be generated. These water vapor are easy to adsorb dust and dirt in the air. When the glass moves on the conveying wheel, the water vapor carrying dust will adhere to the surface of the glass, forming a dust mark; On the other hand, after long-term use, the surface of the conveying wheels will accumulate impurities such as oil stains and dust. In winter, there is more water vapor, and these impurities are more likely to transfer to the glass, especially after being blown by a fan, the gray marks will be more obvious and difficult to remove.

針對這個問題,有幾個簡單有效的解決方法,操作人員可以直接上手嘗試。首先,要做好生產(chǎn)線周邊的防塵和控濕工作。可以在生產(chǎn)線周圍安裝防塵罩,減少空氣中的灰塵含量;同時適當控制車間濕度,避免水汽過度積聚,從源頭減少灰塵和水汽的結(jié)合。其次,定期清潔輸送輪子是關(guān)鍵。每天開工前和收工后,用干凈的抹布蘸取中性清潔劑,仔細擦拭輸送輪子表面,清除附著的油污和粉塵,必要時可以更換磨損嚴重的輪子,避免雜質(zhì)反復(fù)轉(zhuǎn)移到玻璃上。

There are several simple and effective solutions to this problem that operators can directly try out. Firstly, it is necessary to ensure dust and moisture control around the production line. Dust covers can be installed around the production line to reduce the dust content in the air; At the same time, appropriately control the humidity in the workshop to avoid excessive accumulation of water vapor and reduce the combination of dust and water vapor from the source. Secondly, regular cleaning of the conveyor wheels is crucial. Before and after work every day, use a clean cloth dipped in neutral detergent to carefully wipe the surface of the conveying wheels, remove any attached oil and dust, and replace severely worn wheels if necessary to avoid impurities repeatedly transferring to the glass.

另外,還要優(yōu)化水加熱和風機運行的配合參數(shù)。可以適當調(diào)整水溫,不一定非要固定在38度,根據(jù)車間實際溫度微調(diào),減少水汽產(chǎn)生;同時調(diào)整風機的風速和吹風角度,避免強風直接將灰塵吹到玻璃表面,也能減少灰印的形成。如果已經(jīng)出現(xiàn)了輪子灰印,輕度的可以用干凈的無塵布蘸取少量清水輕輕擦拭,嚴重的則需要重新進行玻璃清洗工序,確保產(chǎn)品質(zhì)量。

In addition, it is necessary to optimize the coordination parameters between water heating and fan operation. The water temperature can be adjusted appropriately, not necessarily fixed at 38 degrees. Adjust it according to the actual temperature in the workshop to reduce the generation of water vapor; Simultaneously adjusting the wind speed and blowing angle of the fan can prevent strong winds from directly blowing dust onto the glass surface and reduce the formation of dust marks. If wheel dust marks have already appeared, mild cases can be gently wiped with a clean dust-free cloth dipped in a small amount of water, while severe cases require a new glass cleaning process to ensure product quality.

除了冬天的輪子灰印問題,中空玻璃生產(chǎn)線還有幾個常見的日常難題需要注意。比如玻璃清洗不徹底,會影響后續(xù)密封效果,解決辦法是定期檢查清洗毛刷和噴淋系統(tǒng),確保毛刷無磨損、噴淋無堵塞,同時控制好清洗水溫;還有密封膠打膠不均勻,容易導(dǎo)致中空玻璃漏氣進水,這就需要定期校準打膠設(shè)備,規(guī)范操作人員的操作流程,避免人為誤差。

In addition to the problem of wheel gray marks in winter, there are several common daily challenges that need to be paid attention to in the production line of insulated glass. For example, incomplete cleaning of glass can affect the subsequent sealing effect. The solution is to regularly check the cleaning brush and spray system to ensure that the brush is not worn and the spray is not blocked, while controlling the cleaning water temperature; Uneven application of sealant can easily lead to air leakage and water ingress in insulated glass. This requires regular calibration of the sealing equipment, standardized operation procedures for operators, and avoidance of human error.

這些日常難題看似不大,但如果不及時解決,很容易影響產(chǎn)品質(zhì)量和生產(chǎn)效率。其實很多難題都是可以通過規(guī)范操作、定期維護來避免的。比如定期對生產(chǎn)線設(shè)備進行全面檢查,包括輸送系統(tǒng)、清洗系統(tǒng)、密封系統(tǒng)等,及時更換磨損部件;操作人員嚴格按照操作規(guī)程作業(yè),不隨意調(diào)整設(shè)備參數(shù);根據(jù)季節(jié)變化優(yōu)化生產(chǎn)環(huán)境,比如冬天做好防塵控濕,夏天做好降溫通風。

These daily challenges may seem small, but if not solved in a timely manner, they can easily affect product quality and production efficiency. In fact, many difficulties can be avoided through standardized operations and regular maintenance. For example, regular comprehensive inspections of production line equipment, including conveying systems, cleaning systems, sealing systems, etc., and timely replacement of worn parts; Operators strictly follow the operating procedures and do not adjust equipment parameters arbitrarily; Optimize the production environment according to seasonal changes, such as dust and humidity control in winter and cooling and ventilation in summer.

中空玻璃生產(chǎn)線的穩(wěn)定運行,離不開對日常難題的及時應(yīng)對和規(guī)范的設(shè)備維護。冬天的輪子灰印問題,只要找對成因,通過防塵控濕、清潔輪子、優(yōu)化參數(shù)等方法就能有效解決。希望這次科普能幫到從事中空玻璃生產(chǎn)的朋友們,在日常生產(chǎn)中少走彎路,提升產(chǎn)品質(zhì)量和生產(chǎn)效率。如果遇到其他具體難題,也可以針對性地排查原因,精準解決。

The stable operation of the insulated glass production line relies on timely response to daily problems and standardized equipment maintenance. The problem of wheel dust marks in winter can be effectively solved by identifying the cause, controlling dust and humidity, cleaning the wheels, optimizing parameters, and other methods. I hope this science popularization can help friends engaged in the production of insulating glass to avoid detours in daily production, improve product quality and production efficiency. If you encounter other specific difficulties, you can also investigate the causes specifically and solve them accurately.

本文由 中空玻璃生產(chǎn)線 友情奉獻.更多有關(guān)的知識請點擊 http://www.yalais.com/ 真誠的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識我們將會陸續(xù)向大家奉獻.敬請期待.

This article is a friendly contribution from the insulating glass production line For more related knowledge, please click http://www.yalais.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 中空玻璃打膠機,助您開啟高效生產(chǎn)新時代! 2026/02/19

- 中空玻璃生產(chǎn)線打膠機傳送V帶不平衡?這樣調(diào),傳送平穩(wěn)不跑偏 2026/02/13

- 中空玻璃生產(chǎn)線打膠難題:壓力夠卻打不滿膠?這樣排查就解決 2026/02/12

- 全自動封膠線實操科普:山東昌盛板壓段,筑牢封膠質(zhì)量核心防線 2026/02/10

- 中空玻璃生產(chǎn)線實操科普:小玻璃清洗機反轉(zhuǎn)打滾?這樣解決最省心 2026/02/06

- 全自動封膠線實操科普:白膠泵密封圈這樣換,杜絕漏膠保順暢 2026/02/04

- 雙組份打膠機實操科普:出膠體這樣保養(yǎng)維護,延長壽命保順暢 2026/02/02

- 中空玻璃生產(chǎn)線:清洗機這樣保養(yǎng),清潔高效更耐用 2026/01/30

- 全自動封膠線實操科普:板壓壓合效果差?四角落差這樣調(diào)精準 2026/01/28

- 雙組份打膠機實操科普:黑膠泵過濾這樣清洗,避免堵塞保順暢 2026/01/27

產(chǎn)品分類Product categories

產(chǎn)品分類Product categories

聯(lián)系我們Contact us

聯(lián)系我們Contact us

- 咨詢熱線:0531-85717458 13705446998

- 公司地址: 山東省德州市齊河安頭鄉(xiāng)企巢工業(yè)園

- 掃碼聯(lián)系我們:

當前位置:

當前位置: