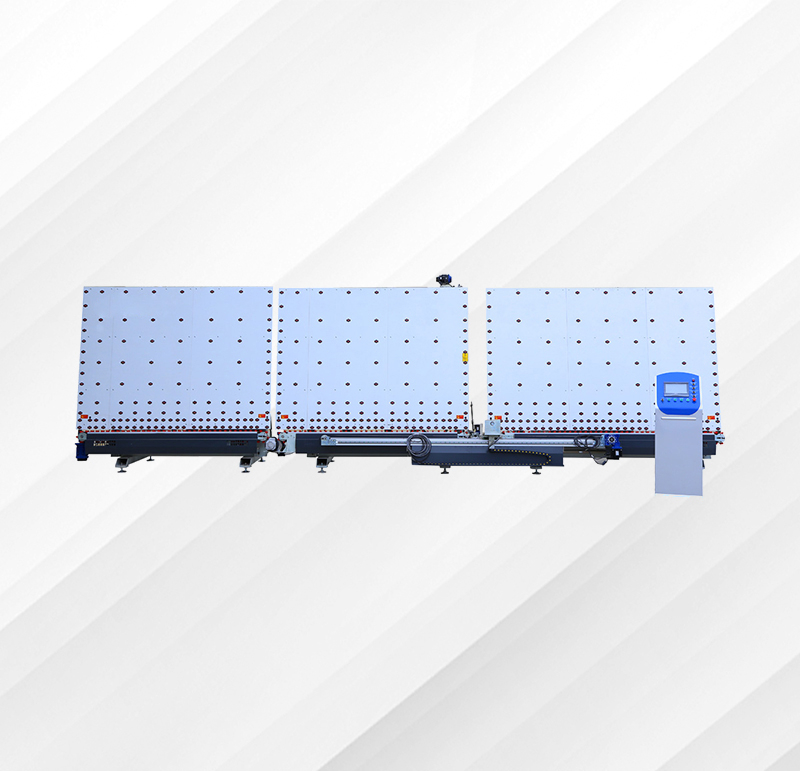

雙組份打膠機和熱熔膠打膠機的產品對比

時間:2022-01-18 來源:http://www.yalais.com/ 發布人:昌盛機械

初次使用雙組份打膠機會有出膠不穩的情況,跟工人的操作熟練度和掌控度有關系,我這用了2天左右就熟練掌握了雙組份打膠機的操作。除了操作熟練,應該跟機器的也有關系。我這用的濟南皓德的,出膠還算穩定。這是它們公司的產品介紹:機架采用整體焊接,龍門架、焊接三角形構成穩定結構,克服懸臂梁工作時的搖動,B泵采用雙立柱,壓盤雙道密封,徹底解決黑組份膠易氧化泄漏的難題;優化管路設計,解決產品流速慢的問題。

When I first used the two-component gluing machine, the glue was unstable, which was related to the operation proficiency and control of the workers. It took me about 2 days to master the operation of the two-component gluing machine. In addition to skilled operation, it should also have something to do with the of the machine. I use Jinan Haode, and the glue is stable. This is the product introduction of their company: the frame is welded as a whole, and the gantry and welded triangle form a stable structure to overcome the shaking of the cantilever beam during operation. Pump B adopts double columns and pressure plate double seals, which completely solves the problem of easy oxidation and leakage of black component glue; Optimize pipeline design to solve the problem of slow product flow rate.

因雙組份打膠機是全氣動控制機型,為了使用戶更好地使用好該設備,故建議在使用前務必仔細閱讀本說明書并嚴格遵照下列要求進行操作。

Since the two-component glue applicator is a fully pneumatic control model, in order to enable users to better use the equipment, it is recommended to carefully read this manual before use and operate in strict accordance with the following requirements.

一、接通氣源:

1、 Connect the air supply:

本機預留氣管接口為PU12快插接頭。

The reserved air pipe interface of this machine is pu12 quick plug connector.

氣源接通,調節減壓閥至0.4~0.6Mpa,檢查系統有無漏氣現象。然后試運行以下動作:(1)A泵提升;(2)A泵充氣;(3)B泵提升;(4)B泵充氣。注意:提升氣缸提升時,如果兩氣缸不同步,請下降至原點后重新操作。

Connect the air source, adjust the pressure reducing valve to 0.4 ~ 0.6MPa, and check the system for air leakage. Then test run the following actions: (1) pump a lifting; (2) A pump inflation; (3) B pump lifting; (4) B pump inflation. Note: when lifting the lifting cylinder, if the two cylinders are not synchronized, please lower to the original point and operate again.

二、將A、B組份膠桶就位,并與A、B膠泵的軸線對中。

2、 Put the rubber drums of components a and B in place and align them with the axis of rubber pumps a and B.

以A組份為例:

Take component A as an example:

1、操作手動轉閥,將A泵提升至高,提升過程中觀察各管路有無拉伸過緊處。

1. Operate the manual rotary valve to lift pump a to the maximum. During the lifting process, observe whether each pipeline is stretched or too tight.

2、將膠桶放置在A泵壓膠盤下,開啟膠桶,將其中塑料袋外翻至桶外,膠面塑料片取出。

2. Place the rubber bucket under the pressure plate of pump a, open the rubber bucket, turn the plastic bag out of the bucket, and take out the plastic sheet on the rubber surface.

3、使A泵壓盤緩慢下降,壓盤入桶時應使其與桶口對準,將壓膠盤排氣口打開,直到壓盤接觸膠面。待壓盤內氣體全部排放完并有少量膠從排氣口溢出時,即可關閉排氣閥。(提升開關保持下壓狀態)

3. Slowly lower the pressure plate of pump a, align the pressure plate with the barrel opening when entering the barrel, and open the exhaust port of the pressure plate until the pressure plate contacts the rubber surface. When all the gas in the pressure plate is discharged and a small amount of glue overflows from the exhaust port, close the exhaust valve. (lift switch remains depressed)

4、開機試打膠:將主泵氣源開關打開,按下膠槍開關,直至A泵里空氣排凈槍口處出膠連續時停止。

4. Start up and try gluing: turn on the air source switch of the main pump and press the glue gun switch until the air in pump a is exhausted and the glue is continuously discharged from the muzzle.

用同樣的方法操作B泵。

Operate pump B in the same way.

以上就是今天小編給大家提供的精彩內容,更多的精彩內容請點擊進入我們的官方網站:雙組份打膠機http://www.yalais.com

The above is the wonderful content provided by Xiaobian today. For more wonderful content, please click to enter our official website: two-component gluing machine http://www.yalais.com

- 中空玻璃打膠機,助您開啟高效生產新時代! 2026/02/19

- 中空玻璃生產線打膠機傳送V帶不平衡?這樣調,傳送平穩不跑偏 2026/02/13

- 中空玻璃生產線打膠難題:壓力夠卻打不滿膠?這樣排查就解決 2026/02/12

- 全自動封膠線實操科普:山東昌盛板壓段,筑牢封膠質量核心防線 2026/02/10

- 中空玻璃生產線實操科普:小玻璃清洗機反轉打滾?這樣解決最省心 2026/02/06

- 全自動封膠線實操科普:白膠泵密封圈這樣換,杜絕漏膠保順暢 2026/02/04

- 雙組份打膠機實操科普:出膠體這樣保養維護,延長壽命保順暢 2026/02/02

- 中空玻璃生產線:清洗機這樣保養,清潔高效更耐用 2026/01/30

- 全自動封膠線實操科普:板壓壓合效果差?四角落差這樣調精準 2026/01/28

- 雙組份打膠機實操科普:黑膠泵過濾這樣清洗,避免堵塞保順暢 2026/01/27

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us