自動點膠機焊接不良的問題的處理方法

時間:2019-03-20 來源:http://www.yalais.com/ 發布人:昌盛機械

自動點膠機焊接過程中,會遇到焊接不良的問題,這些問題詳細表現有漏焊、虛焊、連焊、焊點不潤滑等現象的,濟南雙組份打膠機廠家提示大家,針對這些焊接不良問題,我們認真察看,找出構成這些不良的緣由,然后再有針對性的去處置。

In the welding process of automatic dispensing machine, we will encounter problems of poor welding. These problems are manifested in detail as missed welding, virtual welding, continuous welding, non-lubrication of solder joints and so on. Jinan two-component dispensing machine manufacturer reminds us that in view of these welding problems, we should carefully observe and find out the causes of these defects, and then deal with them pertinently.

1、漏焊。漏焊普通是指在焊接過程中,焊盤上沒有錫的現象。自動點膠機呈現這種情況的緣由大致有兩點,一是烙鐵頭沒有接觸到焊點,這個時分我們就要調整該點的坐標,使烙鐵頭接觸到焊點,這樣就不會呈現漏焊;在一個就是焊盤外表氧化比擬嚴重,錫基本粘不在上面。

1. Leakage welding. Leakage welding generally refers to the phenomenon that there is no tin on the pad during the welding process. There are roughly two reasons for this situation in automatic dispensing machine. One is that the soldering head does not touch the solder joint. At this time, we need to adjust the coordinates of the spot so that the soldering head touches the solder joint, so that there will be no leak soldering; the other is that the surface of the soldering pad is oxidized seriously, and the tin is basically not adhered to it.

2、虛焊。虛焊普通是指在焊接過程中看上去焊點還能夠,實踐上焊接時不撈的或是透錫量不行。構成這種情況的緣由首要是烙鐵頭在焊盤上的停留時間不行或是溫渡過低構成的。因此我們只需延伸烙鐵頭的停留時間或是升高溫度就能夠處置的

2. Virtual welding. Virtual welding generally means that the solder joint can be seen in the process of welding, but in practice it is not salvaged or tin penetration is not good. The main reason for this situation is that the retention time of the soldering head on the pad is not good or the temperature is too low. So we only need to extend the residence time of the soldering head or raise the temperature to dispose of it.

3、連焊。連焊普通是指緊鄰的幾個兩個焊點或是幾個焊點的焊盤鏈接在一同的現象。構成此種現象的緣由要么是送錫量太多或是兩個點之間的空隙太小所構成的。遇到這種情況,應該削減錫量,然后在看能否是烙鐵頭的方位能否正確,如不正確,應及時停止調整

3. Continuous welding. Continuous welding usually refers to the phenomenon that several adjacent solder joints or pads of several solder joints are linked together. The reason for this phenomenon is either too much tin feeding or too small gap between the two points. In this case, we should first reduce the amount of tin, and then see if the orientation of the iron head is correct. If not, we should stop adjusting in time.

4焊點不潤滑、拉尖。焊點不潤滑、拉尖是指焊過之后焊點成型欠好或是有毛刺并有拉尖的現象。此種緣由首要是由于錫的活動性欠好構成的,這個有時分也和我們參數的設置欠好也是有一定緣由的,要么就是停留時間過長,構成助焊劑蒸發過快,在烙鐵頭的抬起過程中就會構成拉尖的現象。這個假設經過參數的設置無法處置的話,我們就要思索錫絲的問題。

4. The solder joint is not lubricated and sharp. Unlubricated solder joints and pointed solder joints refer to the phenomenon of poor solder joint formation or burr and pointed solder joints after soldering. This is mainly due to the inadequate activity of tin, which is sometimes due to the inadequate setting of our parameters. Either the residence time is too long and the flux evaporates too fast, which will lead to the phenomenon of tightening during the lifting process of the soldering head. If this assumption can not be dealt with by setting parameters, we should consider the problem of tin wire.

后,在焊接過程中,呈現上述這些不良焊點的緣由也有可能是由于烙鐵頭該換而沒有及時改換。更多關于雙組份打膠機的精彩內容請收藏我們的官網:http://linshi.jncsjx.com謝謝支持。

Finally, in the welding process, the reason for these bad solder joints may also be that the soldering head should be replaced instead of being replaced in time. More interesting information about the two-component glue machine can be found on our website: http://linshi.jncsjx.com. Thank you for your support.

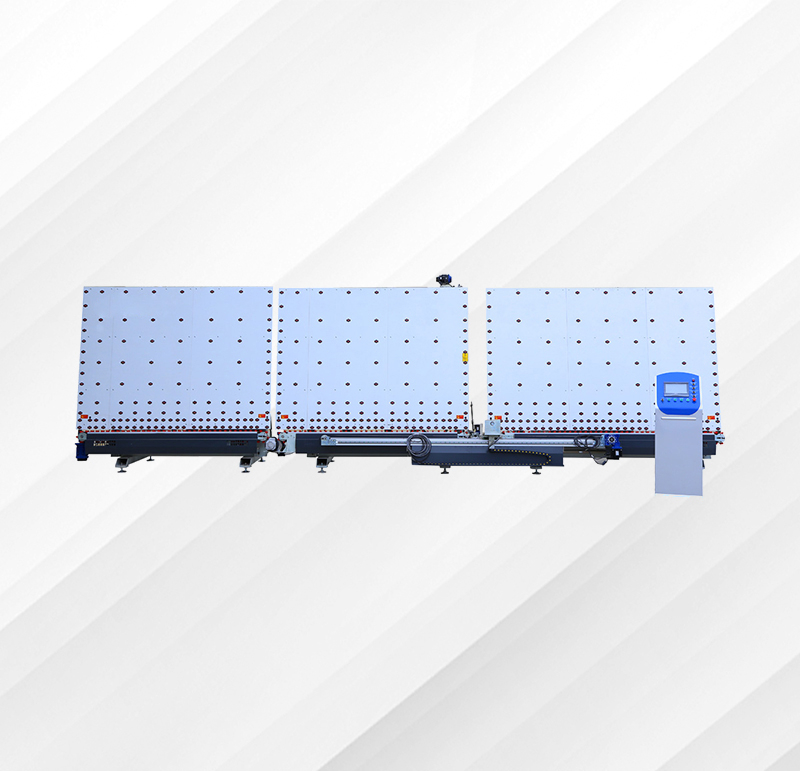

- 中空玻璃打膠機,助您開啟高效生產新時代! 2026/02/19

- 中空玻璃生產線打膠機傳送V帶不平衡?這樣調,傳送平穩不跑偏 2026/02/13

- 中空玻璃生產線打膠難題:壓力夠卻打不滿膠?這樣排查就解決 2026/02/12

- 全自動封膠線實操科普:山東昌盛板壓段,筑牢封膠質量核心防線 2026/02/10

- 中空玻璃生產線實操科普:小玻璃清洗機反轉打滾?這樣解決最省心 2026/02/06

- 全自動封膠線實操科普:白膠泵密封圈這樣換,杜絕漏膠保順暢 2026/02/04

- 雙組份打膠機實操科普:出膠體這樣保養維護,延長壽命保順暢 2026/02/02

- 中空玻璃生產線:清洗機這樣保養,清潔高效更耐用 2026/01/30

- 全自動封膠線實操科普:板壓壓合效果差?四角落差這樣調精準 2026/01/28

- 雙組份打膠機實操科普:黑膠泵過濾這樣清洗,避免堵塞保順暢 2026/01/27

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us