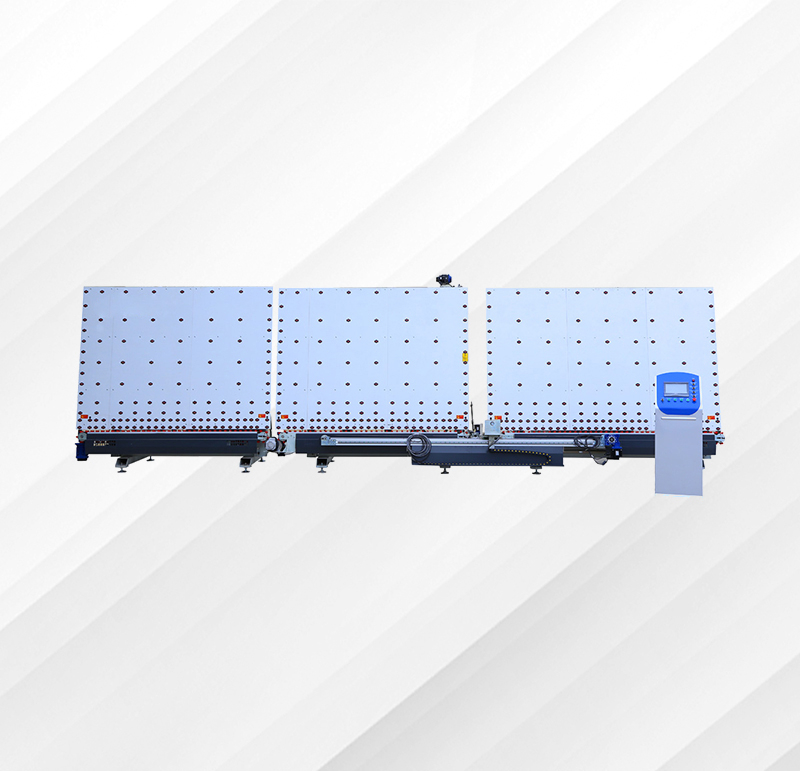

?中空玻璃生產(chǎn)線的操作規(guī)程介紹

時(shí)間:2023-12-13 來源:http://www.yalais.com/ 發(fā)布人:昌盛機(jī)械

一、準(zhǔn)備工作 1、開啟總電源;

1、 Preparation 1: Turn on the main power supply;

2、水箱注滿誰,每班生產(chǎn)前30分鐘開啟水加熱器;

2. Who fills the water tank? Turn on the water heater 30 minutes before each production shift;

3、開啟傳送、加熱、檢查燈、風(fēng)機(jī)、毛刷、水泵。

3. Turn on transmission, heating, inspection lights, fans, brushes, and water pumps.

二、操作步驟

2、 Operation steps

1、將玻璃放入清洗機(jī)進(jìn)料段,手推玻璃進(jìn)入清洗段,玻璃經(jīng)清洗干燥到出料段;

1. Put the glass into the feeding section of the cleaning machine, manually push the glass into the cleaning section, and the glass is cleaned and dried to the discharge section;

2、在出料段檢查玻璃清洗質(zhì)量;

2. Check the quality of glass cleaning in the discharge section;

3、玻璃進(jìn)入覆片機(jī),到達(dá)終點(diǎn)接近開關(guān)時(shí),玻璃自動(dòng)停在定位柱處;

3. When the glass enters the laminating machine and reaches the endpoint close to the switch, the glass automatically stops at the positioning column;

4、覆片機(jī)末端設(shè)有腳踏電開關(guān),踩腳踏開關(guān),鋁框定位移出,將打好膠的鋁框定位安放,再次踩腳踏開關(guān),鋁框定位縮回;

4. The end of the laminating machine is equipped with a foot switch. When the foot switch is pressed, the aluminum frame is positioned and moved out. The glued aluminum frame is positioned and placed. When the foot switch is pressed again, the aluminum frame is positioned and retracted;

5、與上步驟同時(shí),第二片玻璃經(jīng)清洗干燥后,已經(jīng)自動(dòng)停在清洗機(jī)出料段末端的接近開關(guān)處待用;

5. At the same time as the previous step, the second piece of glass has been cleaned and dried, and has automatically stopped at the proximity switch at the end of the discharge section of the cleaning machine for use;

6、將第二片玻璃人工移到覆片機(jī),與第一篇玻璃合片;

6. Manually move the second piece of glass to the laminating machine and merge it with the first piece of glass;

7、按輥壓合片機(jī)啟動(dòng)按鈕,合好片的玻璃自動(dòng)進(jìn)入輥壓合片機(jī),經(jīng)輥壓,玻璃達(dá)到預(yù)定厚度尺寸;

7. Press the start button of the roller lamination machine, and the glass that has been laminated will automatically enter the roller lamination machine. After rolling, the glass reaches the predetermined thickness size;

8、合好片的玻璃進(jìn)入翻轉(zhuǎn)臺,自動(dòng)停在翻轉(zhuǎn)臺末端,踩腳踏開關(guān)2,臺面放出平料。

8. The closed glass enters the flipping table and automatically stops at the end of the flipping table. Step on foot switch 2 and the flat material is released from the table.

三、每班結(jié)束時(shí),關(guān)閉控制臺上各按鈕,再關(guān)總電源。

3、 At the end of each shift, turn off all buttons on the control panel and then turn off the main power.

四、注意事項(xiàng)

4、 Precautions

1、玻璃在清洗前必須經(jīng)過磨邊,否則會對部分構(gòu)件造成損傷。

1. Glass must undergo edge grinding before cleaning, otherwise it may cause damage to some components.

2、向水箱及軟化水裝置注水的自來水開關(guān)保持開啟且水量充足。

2. The tap water switch for filling the water tank and softening water device remains open and the water volume is sufficient.

3、根據(jù)實(shí)際情況調(diào)節(jié)電器箱內(nèi)的水溫控制器來設(shè)定水溫,一般在15度至50度之間,亦可加中性洗滌劑,以達(dá)到清洗效果。

3. Adjust the water temperature controller inside the electrical box according to the actual situation to set the water temperature, generally between 15 ° C and 50 ° C. Neutral detergent can also be added to achieve cleaning effect.

4、調(diào)節(jié)無級變速器調(diào)速按鈕,根據(jù)玻璃污垢情況調(diào)定傳送速度(通常3m\min左右)

4. Adjust the speed control button of the continuously variable transmission and adjust the transmission speed according to the situation of glass dirt (usually around 3m/min)

5、清洗玻璃厚度為3~12mm,經(jīng)干燥后玻璃后邊緣有微量水珠。

5. The thickness of the cleaned glass is 3-12mm, and after drying, there are trace water droplets on the edge of the glass.

6、人和物不能置于翻轉(zhuǎn)臺的翻轉(zhuǎn)區(qū)域內(nèi),以保證安全。

6. People and objects cannot be placed in the flipping area of the flipping platform to ensure safety.

7、安裝調(diào)整完后,請按照操作說明順序試車,若因調(diào)整不好而引起玻璃破裂,須迅速急停,傳送反轉(zhuǎn)倒出碎玻璃,并清理干凈,以免劃傷毛刷及傳送輥。 8、機(jī)器各部分接地良好。

7. After installation and adjustment, please follow the operating instructions for a test run. If the glass breaks due to poor adjustment, it must be quickly stopped, the conveyor reversed and the broken glass poured out, and cleaned to avoid scratching the brush and conveyor roller. 8. All parts of the machine are well grounded.

- 中空玻璃打膠機(jī),助您開啟高效生產(chǎn)新時(shí)代! 2026/02/19

- 中空玻璃生產(chǎn)線打膠機(jī)傳送V帶不平衡?這樣調(diào),傳送平穩(wěn)不跑偏 2026/02/13

- 中空玻璃生產(chǎn)線打膠難題:壓力夠卻打不滿膠?這樣排查就解決 2026/02/12

- 全自動(dòng)封膠線實(shí)操科普:山東昌盛板壓段,筑牢封膠質(zhì)量核心防線 2026/02/10

- 中空玻璃生產(chǎn)線實(shí)操科普:小玻璃清洗機(jī)反轉(zhuǎn)打滾?這樣解決最省心 2026/02/06

- 全自動(dòng)封膠線實(shí)操科普:白膠泵密封圈這樣換,杜絕漏膠保順暢 2026/02/04

- 雙組份打膠機(jī)實(shí)操科普:出膠體這樣保養(yǎng)維護(hù),延長壽命保順暢 2026/02/02

- 中空玻璃生產(chǎn)線:清洗機(jī)這樣保養(yǎng),清潔高效更耐用 2026/01/30

- 全自動(dòng)封膠線實(shí)操科普:板壓壓合效果差?四角落差這樣調(diào)精準(zhǔn) 2026/01/28

- 雙組份打膠機(jī)實(shí)操科普:黑膠泵過濾這樣清洗,避免堵塞保順暢 2026/01/27

產(chǎn)品分類Product categories

產(chǎn)品分類Product categories

聯(lián)系我們Contact us

聯(lián)系我們Contact us

- 咨詢熱線:0531-85717458 13705446998

- 公司地址: 山東省德州市齊河安頭鄉(xiāng)企巢工業(yè)園

- 掃碼聯(lián)系我們:

當(dāng)前位置:

當(dāng)前位置: