中空玻璃打膠機的打膠環節和中空玻璃之間的關系

時間:2023-12-18 來源:http://www.yalais.com/ 發布人:昌盛機械

可能很多人會疑問,中空玻璃自動打膠機的打膠環節和中空玻璃有什么關系。接下來,小編就給大家一起來說一下中空玻璃自動打膠機的打膠環節和中空玻璃的關系。

Many people may question the relationship between the gluing process of the automatic gluing machine for insulated glass and insulated glass. Next, let's talk about the gluing process of the automatic gluing machine for insulated glass and its relationship with insulated glass.

一塊合格的中空玻璃不僅在于規范的操作流程與完美的工藝技術,更需要能滿足中空玻璃性能的中空玻璃加工設備和與其相關的密封材料。不同的中空玻璃的密封差異可能讓中空玻璃終呈現的工藝成品以及綜合性能不同。

A qualified insulating glass not only requires standardized operating procedures and perfect process technology, but also requires insulating glass processing equipment and related sealing materials that can meet the performance requirements of insulating glass. The sealing differences of different insulating glass may result in different process products and comprehensive performance of insulating glass.

中空玻璃的密封主要采用密封膠,起到中空玻璃的密封作用。中空玻璃的密封,除紫外線照射是測試中空玻璃密封膠是否含有影響視線的有機揮發物外,另外四項指標“密封性能、初始露點、高溫高濕、氣候循環”,都是檢測中空玻璃在各種環境下的密封性能的。中空玻璃的密封主要采用密封膠,起到中空玻璃的密封作用。

The sealing of insulating glass mainly uses sealant, which plays a sealing role in insulating glass. The sealing of insulating glass, in addition to UV radiation testing whether the insulating glass sealant contains organic volatile substances that affect vision, the other four indicators "sealing performance, initial dew point, high temperature and humidity, and climate cycle" are all used to test the sealing performance of insulating glass in various environments. The sealing of insulating glass mainly uses sealant, which plays a sealing role in insulating glass.

槽鋁式雙道密封中空玻璃第一道密封用丁基膠,具有極低的水蒸氣透過率;第二道密封膠主要有聚硫膠和硅酮膠。間隔鋁框宜采用連續長管彎角式,接頭處應用丁基膠做密封處理;間隔鋁框如采用四角插接式,其各個接頭處亦應用丁基膠做密封處理,以此做成的中空玻璃,使用壽命不如前者。當中空玻璃第二道密封膠采用硅酮膠時,不應采用四角插接式間隔鋁框的中空玻璃。

The first sealing layer of the aluminum groove double sealed hollow glass is made of butyl rubber, which has an extremely low water vapor transmission rate; The second layer of sealant mainly includes polysulfide adhesive and silicone adhesive. The interval aluminum frame should adopt a continuous long pipe bending angle type, and the joints should be sealed with butyl adhesive; If the spacing aluminum frame adopts a four corner plug-in type, each joint should also be sealed with butyl rubber, and the hollow glass made from this has a shorter service life than the former. When the second layer of sealant for insulating glass uses silicone adhesive, insulating glass with four corner plug-in spacing aluminum frames should not be used.

單道密封中空玻璃是難以滿足中空玻璃的密封性能的。為彌補這些膠的密封性能的不足,通常采用水汽透過率極低,但結構性差的聚異丁烯膠作為中空玻璃的第一道密封膠,以阻止潮氣向中空玻璃內滲透,這就是傳統的大家熟悉的雙道密封中空玻璃的生產工藝。由于雙道密封中空玻璃所采用的二種密封膠各自性能上的缺陷,只能采用兩者結合的方式(即雙道密封式)才能滿足中空玻璃的密封性和結構性指標。現在有一些新型中空玻璃密封膠:結構型熱熔丁基密封膠。

Single sealed insulating glass is difficult to meet the sealing performance of insulating glass. To compensate for the insufficient sealing performance of these adhesives, polyisobutylene adhesive with extremely low water vapor permeability but poor structure is usually used as the first sealant of insulating glass to prevent moisture from penetrating into the insulating glass. This is the traditional production process of double sealed insulating glass, which is familiar to everyone. Due to the performance defects of the two types of sealants used in double sealed insulating glass, only a combination of the two (i.e. double sealed) can meet the sealing and structural indicators of insulating glass. There are now some new types of hollow glass sealants: structural hot melt butyl sealants.

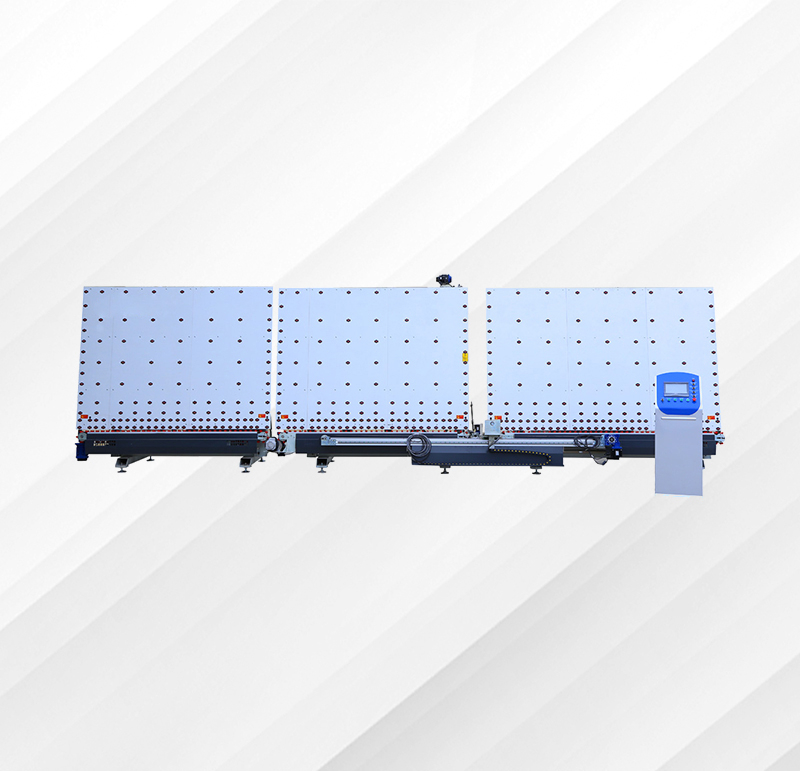

中空玻璃打膠機主要用于中空玻璃的打膠環節,也就是我們平時所說的密封環節。中空玻璃打膠機主要針對中空玻璃的第一道密封。使用專用設備將熱熔丁基膠加熱熔化后,用中空玻璃打膠機將丁基膠涂至中空玻璃的涂膠部位。這個打膠速度要掌握好,因為丁基膠幾分鐘就冷卻定型,打膠速度不宜過快過慢。過快的情況下很容易導致打膠不飽滿,日后影響中空玻璃的密封問題。過慢的情況下影響中空玻璃打膠機的工作效率問題。

The insulated glass gluing machine is mainly used for the gluing process of insulated glass, which is commonly referred to as the sealing process. The insulating glass gluing machine is mainly designed for the first sealing of insulating glass. After using specialized equipment to heat and melt the hot melt butyl adhesive, apply the butyl adhesive to the coating area of the hollow glass using a hollow glass gluing machine. The gluing speed needs to be controlled well, because butyl rubber cools down and forms shape in a few minutes, and the gluing speed should not be too fast or too slow. If the glue is applied too quickly, it is easy to cause insufficient filling, which will affect the sealing of the hollow glass in the future. The problem of affecting the efficiency of the hollow glass gluing machine when it is too slow.

感謝您的閱讀,此文的文章來源:中空玻璃加工設備更多的內容和問題請點擊:http://www.yalais.com 我們會繼續努力的為您提供服務,感謝您的支持!

Thank you for reading. The source of this article is: Hollow Glass Processing Equipment. For more information and questions, please click: http://www.yalais.com We will continue to work hard to provide you with services. Thank you for your support!

- 中空玻璃打膠機,助您開啟高效生產新時代! 2026/02/19

- 中空玻璃生產線打膠機傳送V帶不平衡?這樣調,傳送平穩不跑偏 2026/02/13

- 中空玻璃生產線打膠難題:壓力夠卻打不滿膠?這樣排查就解決 2026/02/12

- 全自動封膠線實操科普:山東昌盛板壓段,筑牢封膠質量核心防線 2026/02/10

- 中空玻璃生產線實操科普:小玻璃清洗機反轉打滾?這樣解決最省心 2026/02/06

- 全自動封膠線實操科普:白膠泵密封圈這樣換,杜絕漏膠保順暢 2026/02/04

- 雙組份打膠機實操科普:出膠體這樣保養維護,延長壽命保順暢 2026/02/02

- 中空玻璃生產線:清洗機這樣保養,清潔高效更耐用 2026/01/30

- 全自動封膠線實操科普:板壓壓合效果差?四角落差這樣調精準 2026/01/28

- 雙組份打膠機實操科普:黑膠泵過濾這樣清洗,避免堵塞保順暢 2026/01/27

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us